Diamond-like carbon (DLC) with excellent lubricating and protective properties has been widely used in engineering devices. However, conventional vapor deposition methods, such as physical vapor deposition, chemical vapor deposition and plasma enhanced chemical vapor deposition, are only limited to be used for outside surfaces of devices or internal surfaces with long diameter and small length/diameter ratio.

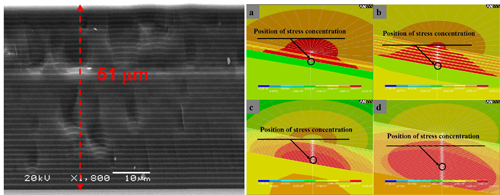

The research group headed by Professor XUE Qunji and Professor WANG Liping at the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has developed a plane hollow cathode plasma enhanced chemical vapor deposition method (PHC-PECVD). The PHC-PECVD method allows deposition of superthick (Six-DLC/Siy-DLC)n/DLC films with thickness of more than 50 μm. The thick (Six-DLC/Siy-DLC)n/DLC film exhibits superior mechanical properties. The hardness and adhesion strength of the film are measured up to 22 GPa and 65 N, respectively. In addition, the thick DLC film exhibits high sliding wear resistance and low friction in three environments, namely, air, water, and oil.

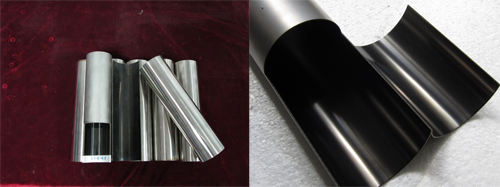

With the PHC-PECVD, the deposition rate of the films can reach 100nm~500nm/min and the films can be uniformly deposited on internal surfaces of pipes with the length/diameter ratio of 20. The technique can be applied to internal surfaces of pipes with diameter ranging from 10 mm to 30 mm.

Furthermore, researchers have used static and dynamic finite element analysis to study the correlation between computer simulation of failure and coupling process of films and the experimental results. They have put forward the service life-extending mechanism of the films from the perspectives of micro-structure of films, environment and friction condition.

The newly developed technique is expected to be applied in industrial pipes, valves, pumps and so on. In addition, researchers have obtained a Chinese invention patent concerning technique and the patent number is ZL201110012884.9.

The work has been published in ACS Applied Materials & Interfaces(ACS Applied Materials & Interfaces, 2013, 5, 5015-5024).

DLC-coated surfaces (Image by WANG Liping et al.)

SEM and finite element analysis of the fracture of (Six-DLC/Siy-DLC)n/DLC-coated (Image by WANG Liping et al.)