Ocean, which covers 71% of the earth’s surface and contains abundant resources, is the treasure house of resources that ensures further development of human society. Along with the springing up of blue revolution of exploiting ocean all over the world, attention has been increasingly paid to the application performance including mechanical properties and friction and wear behavior of various materials in ocean environment.

As a widely used and key technology in ocean exploitation, seawater hydraulic drive system has rigorous requirements for frictional pair materials, which means the materials used for seawater tribological application must possess excellent wear resistance and corrosion resistance therein. Thus, it is imperative and urgent to develop seawater-lubricated materials used for seawater hydraulic drive and investigate their friction and wear behavior and wear mechanisms as well.

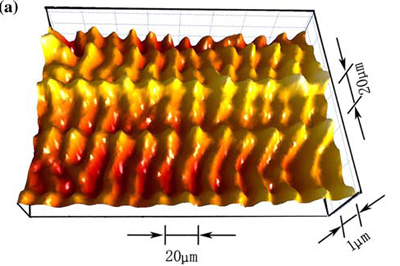

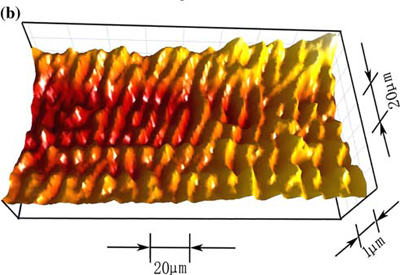

Recently, a paper entitled “Friction and Wear Behavior of Ultra-High Molecular Weight Polyethylene Sliding Against GCr15 Steel and Electroless Ni–P Alloy Coating Under the Lubrication of Seawater” and published in Tribol Lett (Tribol Lett (2009) 35:85–95) journal by the research group of the Lanzhou Institute of Chemical Physics, CAS, just dealt with such problems. Headed by Academician Xue Qunji and Prof. Yan Fengyuan, the researchers investigated the friction and wear behavior of ultra-high molecular weight polyethylene (UHMWPE) sliding against GCr15 steel and electroless Ni-P alloy coating under the lubrication of seawater and compared it with that under dry sliding and lubrication of pure water and 3.5 wt.% NaCl solution, respectively. They have found that under the lubrication of aqueous medium, the friction and wear behavior of UHMWPE mainly depended on the corrosion of counterface and the lubricating effect of the medium. Because of serious corrosion of counterface by the medium, the wear rates of UHMWPE sliding against GCr15 under the lubrication of seawater and NaCl solution were much larger than that under other conditions, and such a kind of wear closely related to the corrosion of counterface can be reckoned as indirect corrosive wear. However, when sliding against corrosion-resistant Ni–P alloy under the lubrication of seawater, the lowest coefficient of friction and wear rate of UHMWPE were obtained, owing to superior lubricating effect of seawater. Moreover, periodic ripple patterns were observed on the worn surfaces of UHMWPE sliding against GCr15 under the lubrication of seawater and NaCl solution, which were ascribed to the intelligent reconstruction of surface microstructure of UHMWPE upon large plowing effect of the counterface asperities. Based on scanning electron microscopic (SEM) and three-dimensional (3D) profile analyses of the worn surfaces of UHMWPE, researchers proposed a stick–slip dynamic mechanism to illustrate the pattern abrasion of UHMWPE.

The research is a big step forward in the tribological application of UHMWPE in seawater environment and is financially supported by National High-Tech Research and Development Program of China and National Natural Science Foundation of China.

3D profiles of abrasion patterns formed on the worn surfaces

of UHMWPE. a Under 3.5 wt.% NaCl solution lubrication. b Under

seawater lubrication

Abstract of the article published inTribol Lett

|