A comparative study on tribological properties of both nano-eutectic and annealed coarse grained Fe1.87C0.13 alloys under liquid paraffine-lubricated conditions has been carried out by the State Key Laboratory of Solid Lubrication, LICP, CAS.

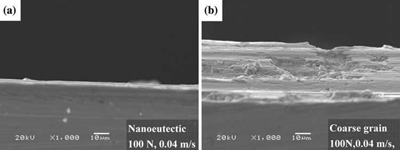

Results indicate that the wear rate of the two alloys increases with increasing applied load and sliding speed, but the friction coefficient does not have obvious relation with the applied load and sliding speed. The wear resistance of the nano-eutectic Fe1.87C0.13 alloy enhances about 2–20 times compared with that of the annealed coarse-grained Fe1.87C0.13 alloy at present experimental conditions, which is attributed to the higher hardness and formation of more stable lubricating film/layer for the nano-eutectic alloy in friction process. However, the friction coefficients of the two alloys are almost the same under liquid paraffine lubricated condition. The wear mechanism of the nano-eutectic Fe1.87C0.13 alloy is transformed from plowing to fatigue flaking pits with increasing applied load and sliding speed, but that of the annealed coarse-grained Fe1.87C0.13 alloy is transformed from plowing to fatigue flaking pits then to serious fatigue wear.

Previous research on the tribological properties of the nanostructured materials mainly focuses on the dry-sliding condition. However, in most cases, the tribological parts are used under oil lubrication. Thus, it is valuable in science and technology to investigate the tribological performance of the bulk nanostructured Fe–C alloy under liquid paraffine-lubricated condition.

The study was supported by the National Natural Science Foundation of China and the National 973 Project of China and the Innovation Group Foundation from NSFC. The research result was published in Tribol. Lett. (Tribol. Lett. (2010) 37:183–189).

|