New advances in the preparation and application of high performance ceramic lubricating and sealing materials have been achieved by the research group headed by Prof. HU Litian of the R&D Center of Lubricating and Protecting Materials, Lanzhou Institute of Chemical Physics (LICP), CAS.

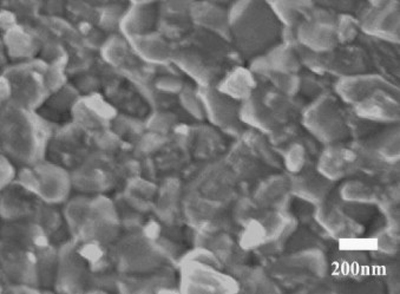

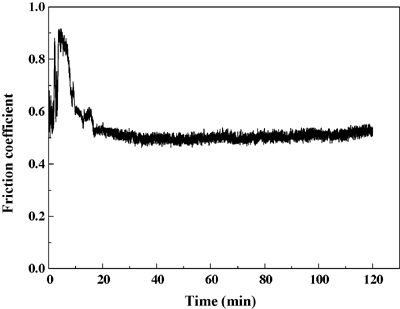

Combining the nano-ceramic technology and ceramic lubrication technology, researchers have prepared Y-TZP/Al2O3/Mo nanocomposites possessing excellent mechanical and tribological properties by the hot-pressed sintered technology. There is mixed-structure composed of intra-granular, inter-granular and nano/nano type in Y-TZP/Al2O3/Mo nanocomposites, which results in high fracture toughness as high as 17.4 MPa·m1/2. A reduced friction coefficient of nanocomposites was gained that was attributed to the formation of friction induced oxide layer during high-temperature friction process. The friction coefficient of the nanocomposites is below 0.5 when sliding against Si3N4 ceramic ball at 800℃. The work was published in the latest issue of Wear (Wear 2010, 268: 1091-1094).

SEM photograph of Y-TZP/Al2O3 ceramic phase in the Y-TZP/Al2O3/Mo nanocomposites

Relationship between friction coefficient and sliding time

High performance ceramic lubricating and sealing materials have been applied widely in aeronautics, astronautics, atomic energy, microelectronics and other fields due to their high temperature resistant, chemical resistant and anti-wear properties, excellent mechanical strength and lubricating properties.

In recent years, through the accurate control of grain size, reinforcing phase composition and structure, reasonable tribological design, Prof. HU’s group has prepared Y-TZP nano-ceramics and its compositeswith excellent mechanical and tribological properties constructed by dispersing second-phase such as Al2O3, TiO2, CuO, Mo, Graphite andMoS2. The fracture toughness and bending strength of the materials can reach 17.4 MPa·m1/2 and 1300 MPa respectively. The friction coefficient is as low as 0.25 and wear rate is below 1.0×10-6 mm3/N·m.

Basing on the systematic research on the structure, preparation and performance of nano-ceramics, new factors influencing the sintering, mechanical and tribological properties of nano-ceramics were proposed and the theoretical model for the wear of this type of materials was constructed.

The above-mentioned work was published in the world renowned journals, such as Adv. Eng. Mater. (2006, 8: 271-275), Mater. Lett. (2006, 60: 2302-2305), J. Am. Ceram. Soc. (2008, 91: 1332-1334), J. Mater. Process. Technol. (2008, 198: 191-194; 2009, 209: 1533-1537) and Wear(2010, 268: 1091-1094).

The work was supported by the National Natural Science Foundation of China and the Basic Research Project of the China Aerospace Science and Technology Corporation.

Abstract of the paper published in Wear (2010, 268: 1091-1094)

|