New advance in the fabrication and protection behaviors of gradient multi-layered carbon-based composite coatings on aluminum alloys was made by the Research Group of Tribology of Low Dimensional Materials, State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), CAS.

Light alloy materials, such as aluminum alloys (Al alloys), have been widely used in astronautics, aeronautics, weapons, machinery, automobiles, transportation, petrochemical, textile, printing, etc. The application of light alloy materials in these fields involves the functional protection, friction, wear, corrosion of the surface of the moving parts made of light alloys.

The high hardness, excellent wear and corrosion resistance, low friction nature, and high chemical stability of diamond-like carbon (DLC)-based composite coatings make them good candidates as protective layers for aluminum alloys. Unfortunately, the abrupt changes in hardness and thermal expansion coefficient between coating/substrate interface resulted in the poor adhesion strength, low load-carrying ability, easily deformation and cracking of hard a-C:H coatings during the wear process. The anti-wear property of the protective DLC coatings is poor under variable working conditions and corrosion environments. The coatings can easily peel from the aluminum alloy substrate, which eventually results in coatings failure.

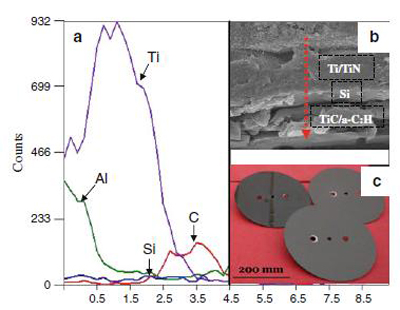

By a combined multi-arc ion plating and magnetron sputtering process, the research group successfully fabricated the gradient multi-layered carbon-based nanocomposite coatings on aluminum alloys.

The key problems, such as the high bonding strengthen between coatings and substrate, simultaneous realization of anti-wear and anti-corrosion, etc, have been solved. Technologies for high-performance carbon-based coatings for the surface of aluminum alloy pistons and blades of automobile air conditioners have been developed.

The gradient multi-layered carbon-based composite coatings on aluminum alloys showed excellent self-lubricating and anti-wear property under dry friction, oil lubricated conditions, corrosion and other variable working conditions. The fabricated carbon-based coatings can improve the anti-wear performance and corrosion resistance of moving parts made of Al alloys in the early running-in wear period and under frequent start/stop conditions and variable working conditions.

The work was supported by the Nature Science Foundation of China and National High-tech R&D Program of China. The detailed report was published in the recent issue of Tribology Letters (Tribology Letters 2010, 38: 155-160).

a EDS depth profile of the Ti/TiN/Si/(TiC/a-C:H) coatings, b corresponding SEM micrographs of the fracture cross-sections; and c large-sized aluminum alloy samples coated by DLC-based multilayer with smooth surface and excellent adhesion with substrate