To strengthen the importance of integrating various functional fillers in the design of wear-resistant polymer composite coatings, researchers of the R&D Center of Lubricating and Protecting Materials, Lanzhou Institute of Chemical Physics, CAS, recently studied the tribological behavior of nano-ZnO-filled polyurethane composite coatings.

They first prepared the ZnO nanoparticles and ZnO whiskers reinforced PU composite coatings by spray technique and then evaluated the tribological performances of the coatings under dry sliding condition using an MHK-500 ring-on-block wear tester. The influences of applied load and sliding speed on tribological behavior of the ZnO reinforced PU composite coatings were also investigated.

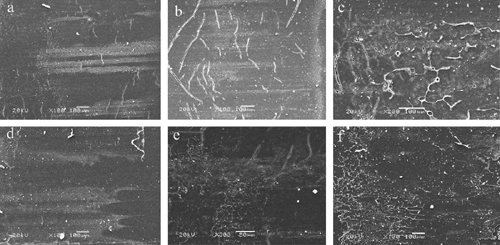

SEM pictures of the worn surfaces of the PU coating reinforced with 5.0 wt.% ZnO nanoparticles (a–c) and 5.0 wt.% ZnO whiskers (d–f) under different applied load and sliding speed (60 min): (a) 420 N; (b) 720 N; (c) 3.84 m/s; (d) 420 N; (e) 720 N; (f) 3.84 m/s.

It was found that the addition of the low inclusion of ZnO nanoparticles and ZnO whiskers can improve the reducing-friction and anti-wear abilities of the PU coatings and ZnO whiskers, as the filler was superior to ZnO nanoparticles in terms of the ability to decrease friction coefficient and wear rate of the PU coating. The investigations of the worn surfaces showed that the fillers of ZnO nanoparticles and ZnO whiskers were able to enhance the adhesion of the transfer films of the PU coating to the surface of counterpart ring, so they significantly reduced the wear rate of the PU coating.

Polyurethane coatings have been applied widely due to their excellent gloss, hardness, flexibility, chemical resistance and ultraviolet durability. However, polyurethane materials usually have poor abrasive wear-resistance. To further improve the mechanical and tribological performance of polyurethane-based friction material, one of the traditional concepts is to reduce their adhesion to the counterpart material and to enhance their hardness, stiffness and compressive strength. To reduce adhesion, lubricants such as PTFE and graphite flakes are frequently incorporated. Recently, nanoparticles have been considered for fabrication of the wear-resistant polymer composites since less abrasive action during frictional sliding and greater surface area will contribute to improving the tribological performance.

However, the studies about the tribological behavior of the PU coatings filled with different morphologies nanometer ZnO are still less reported.

The detailed report of the work was published in Wear (Wear 269 (2010) 79–85).

Abstract of the paper published in Wear |