Diamond-like carbon (DLC) has attracted considerable attention in tribological applications owing to their unique combination of properties. Up to date, a large numbers of studies related to the friction and wear properties of the a-C:H films in various environments have been reported. The sand-dust environment is the very important influencing factor for the application of a-C:H films as tribological protective and functional layer in engine and different mechanical systems. However, there is little work in the open literature on the tribological behavior of a-C:H films against a steel pin under natural sand-dust conditions.

Researchers of the State Key Laboratory of Solid Lubrication have made progress in the area. They have tested the a-C:H films produced by magnetron sputtering at four different amount of sand and particle sizes conditions under a series of applied load to investigate their friction and wear properties. And a physical model has also been established to understand the anti-wear mechanisms of material removal for a-C:H films during the abrasive wear process

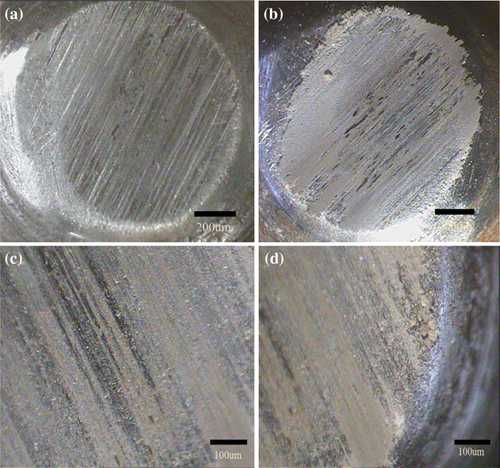

Optical micrograph image of ridge formation on the AISI 1045 steel pin surface after sliding against a-C:H films under the large amount of sand in the 45–97 µm range with the 5 N load and 5 Hz

Results show that a-C:H films exhibited ultra-high tribological performance with low friction coefficient and ultra-low wear rate under sand-dust environments. It is very interesting to observe that the friction coefficient of a-C:H film under sand-dust conditions was relatively lower when compared with dry sliding condition, and the wear rate under sand-dust conditions kept at the same order of magnitude (x10(-19) m(3)/N m) with the increase of applied load and particle size as a comparison with the dry sliding condition. Based on the formation of "ridge" layer (composite transfer layer), a transfer layer-hardening composite model was established to explain the anti-wear mechanisms and friction-reducing capacity of a-C:H solid lubrication films under sand-dust conditions.

The works is financially supported by the National Natural Science Foundation of China and the 863 Program of Chinese Ministry of Science and Technology. The work is published in TRIBOLOGY LETTERS (Tribol. Lett. (2010) 38:195–205).

Abstract of the paper published in TRIBOLOGY LETTERS