Carbon-based composite thin films, especially diamond-like carbon (DLC), have attracted considerate attention in low friction surfaces owing to their combination of properties of high hardness, low friction, etc. However, DLC based composite thin films have the following disadvantages, such as low toughness, high brittleness and low thermal stability; high stress and low adhesion between film and substrate; tribological behavior which is liable to the influence of environment and so on. These have greatly limited the service life and reliability of the films. How to make full use of the advantages of the films under complicated environment and special conditions is a problem deserving great attention.

Based by the concepts of multi-layered gradient, multiple doping, multiphase composite and micro/nano structure, the research group headed by Prof. XUE Qunji and Prof. WANG Liping of the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics (LICP), CAS, have achieved the multi-dimensional strengthening and toughening in the preparation of carbon-based composite films, reliable adhesion and even distribution of carbon-based films on the surfaces of spare parts with special size and shape using multi-functional composite vapor deposition technology. The have also developed high performance carbon based thin film technology for the surfaces of piston rings, engine lifters, valve for refrigerators, compressor blades, mold, etc. The wear failure mechanism of the carbon based thin films under special serving environment has been revealed. The service life extending theory and toughening mold influencing the composite thin film have been put forward.

Their work has received support from the National High-tech R&D Program of China. Six papers concerning the work have been published in Tribology Letters (2010,38:155-160; 2010, 38: 195-205; 2010, 40: 301-310; 2011, 41: 439-449; 2011, 41: 163-170; 2011, 41: 435-438).

Gradient multi-layered carbon-based composite coatings for the surfaces of blades of compressors and pistons of refrigerators (Image by WANG Liping et al.)

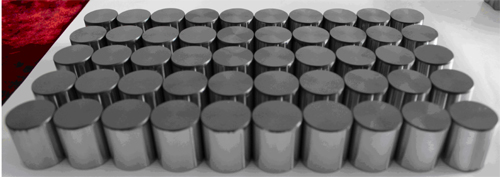

Multi-dimensional strengthening and toughening of carbon-based thin film for the surfaces of automobile engine lifters (Image by WANG Liping et al.)

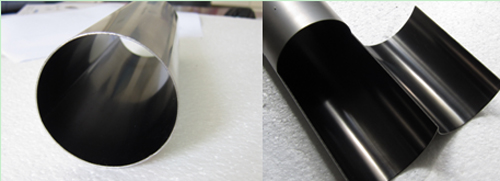

Super thick DLC based thin films on the surfaces of inwall of pipes with special shape (Image by WANG Liping et al.)

Super thick DLC based thin films with large area of deposition (Image by WANG Liping et al.)

Tribology Letters Paper (2010, 38:155-160; )