Researchers at the R&D Center of Lubricating and Protecting Materials of the Lanzhou Institute of Chemical Physics have successfully synthesized network polymers SiO2–shape memory polymers (SiO2–SMP) with excellent shape memory effect and high mechanical strength.

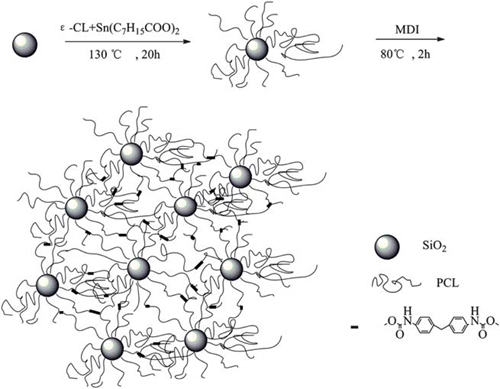

The SiO2–SMP was prepared as follows: (1) the core-shell microsphere SiO2@polycaprolactone(SiO2@PCL) were synthesized by initiating the opening polymerization (ROP) of epsilon-caprolactone (є-CL) on the surface of SiO2, (2) SiO2–SMP polymer network formed via joint two terminal hydroxyls of SiO2@PCL by isocyanines. At room temperature the elastic moduli (E) and tensile strength (σm) of the SiO2–SMP were improved to 500 MPa and 90 MPa, respectively. Furthermore, the mechanical and shape memory properties could be adjusted by changing the size of silica microspheres and the molecular weight of the PCL.

As a stimuli-sensitive material, SMP has already been used in the field of biomedical and textile materials. However, the tensile strength is not yet powerful enough, which limits its application to some degree; therefore the development of SMP with high strength has received significant attention. The existing preparation methods all have some shortcomings, such as the low elongation at break of high strength polymers, complicated preparation process, etc.

The work has received support from the National Foundation for Distinguished Young Scholars of China, Science Fund for Creative Research Groups of the National Natural Science Foundation of China and National Program on Key Basic Research Project of China. The findings have been published in J. Mater. Chem. (J. Mater. Chem., 2011, 21, 9073–9078).

J. Mater. Chem. Paper

Schematic illustration of SiO2–SMP synthesis. (Image by WANG Qihua et al.)