To elucidate the role of sand dust in determining the tribological performance of selected solid lubricant films, researchers have investigated the abrasive wear behaviour of five types of solid lubricant films (magnetron-sputtered diamond-like carbon, magnetron-sputtered molybdenum disulfide, bonded molybdenum disulfide, bonded polytetrafluoroethylene and bonded graphite) in sand dust environment using a reciprocating pin-on-disc test rig. The influence of applied load, amount of sand and particle size have also been examined.

Experimental results show that magnetron-sputtered films give excellent anti-friction and wear resistance performances under sand-dust environments compared to bonded solid lubricant films. The significant differences of surface roughness, hardness, microstructure and intrinsic lubricating property directly lead to the different tribological performances and worn morphology. The formed composite transfer layer plays a vital role in reducing friction and wear due to its anti-friction and shielding action of the film surface from the hard metal asperities. Two main abrasive wear mechanisms (three-body rolling wear and two-body grooving wear) occur simultaneously in the tribological process under sand-dust environments. A transfer layer-hardening composite wear modeling was established to further explain the anti-wear mechanisms and friction-reducing capacity of these solid lubricant films under sand-dust environments.

Solid lubricant coatings are primarily used to control friction and wear under severe application conditions, where conventional materials and lubricants cannot provide the desired levels of performance or durability. Solid lubricant films have come a long way in recent years, and they are now capable of providing extremely low friction and wear coefficients under certain or highly controlled test conditions. Their uses are expected to further increase in coming years, mainly because the operating conditions of future tribosystems are becoming more and more demanding and liquid and grease-type lubricants are undesirable due to environmental concerns. However, the abrasive wear behaviour of these solid lubricant films in sand-dust environment has not received enough attention and extensive research.

The sand-dust environment can be a very important influencing factor for the application of solid lubricant films in tribosystems. Previous studies indicate that one of the best alternatives to resolving the tribological problems of mechanical systems in sand-dust environments is to apply effective protective films with good wear-resistance and friction-reducing capacity on the moving parts.

The work has received support from National Basic Research Program of China (973 Program), National High-tech R&D Program of China (863 Program) and National Natural Science Foundation of China. The findings have been published in Wear (Wear 271 (2011) 899– 910).

Wear Paper

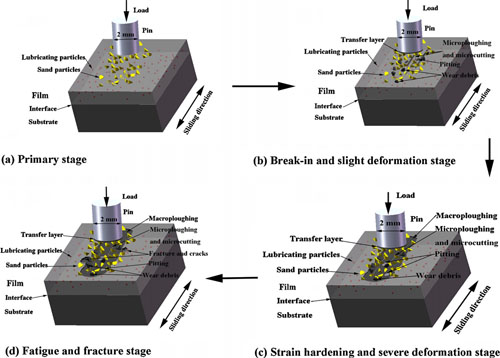

Schematic diagram of wear processes and mechanisms for the counterbody against selected lubricating films.