Binary carbides (e.g. SiC, WC, and TiC) and ternary carbides (e.g. Ti3SiC2) are very important materials for many tribological applications. However, these carbides do not feel self-lubricated under dry sliding.

Researchers at the R&D Center for Lubricating and Protecting Materials, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS) have endowed SiC and Ti3SiC2 with self-lubricating property by fabricating carbide-derived carbon (CDC) coatings on SiC and Ti3SiC2 blocks.

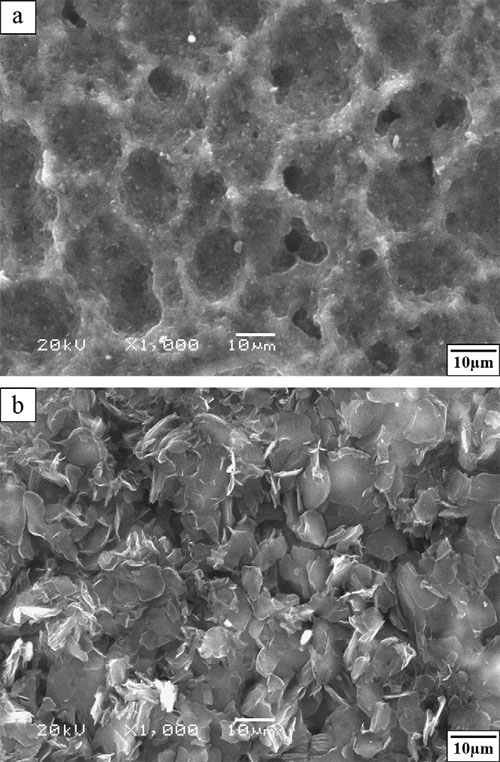

Through chlorination at 1000℃ for 5h, researchers have prepared CDC coatings on SiC and Ti3SiC2 and investigated unlubricated friction and wear of the two CDC coatings in sliding against Si3N4 on an UMT-2MT tribometer with a ball-on-block configuration at room temperature. They also compared the tribological properties of the two CDC coatings and discussed the microstructural effect on the tribological behavior of the CDC coatings on SiC and Ti3SiC2 blocks.

The results showed that CDC coatings on SiC and Ti3SiC2 were self-lubricating in sliding against a Si3N4 ball. The wear of the Si3N4 ball is not measurable. The CDC coating on a SiC block had advantages over the CDC coating on a Ti3SiC2 block in terms of friction coefficient, wear resistance and load-carrying capacity. The typical friction coefficient of the CDC coating on a SiC block was as low as 0.08, which was only ca. 40% of the friction coefficient of the CDC coating on a Ti3SiC2 block. The CDC coating on SiC had a nanocrystalline and disorder structure of carbon and excellent tribological behavior. The CDC coating on Ti3SiC2 was microcrystalline graphite and subject to plastic flow at the tribo-interface and yielded high wear.

The work has received support from the National Natural Science Foundation of China. The findings have been published in Wear (Wear 271 (2011) 1974-1979).

Wear Paper

SEM micrographs of the two CDC coatings on (a) SiC and (b) Ti3SiC2. (Image by LU Jinjun et al.)