Pattern abrasion as a typical wear mechanism of rubber has been extensively investigated. However, abrasion patterns on the worn surfaces of plastic has attracted less attention, especially when it comes to the relation between pattern abrasion and the microstructure transformation of the plastic.

Researchers from the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences have investigated unusual pattern abrasion of ultra-high molecular weight polyethylene (UHMWPE) plastic under the lubrication of aqueous solution of NaCl in relation to the microstructure transformation of UHMWPE.

It is found that Under the plowing effect, the molecular chains and short-rod like microcrystalline grains of abrasion pattern are both further oriented along the plowing direction as compared with that of the initial surface of UHMWPE, resulting in wavelike abrasion pattern of UHMWPE owing to the competition equilibrium between the plowing effect and adhesive effect suffered by the worn surface. Due to the microstructure reconstruction of worn surface associated with the formation of abrasion pattern under plowing effect, the grains of the abrasion pattern become tiny and dense than that of the initial surface, resulting in increased nanoindentation hardness and modulus as well as wear-resistance of UHMWPE.

The work has been financially supported by the National Natural Science Foundation of China and the National High-tech R&D Program of China. The findings habe been published in Wear (Wear 272 (2011) 176– 183 177).

Wear Paper

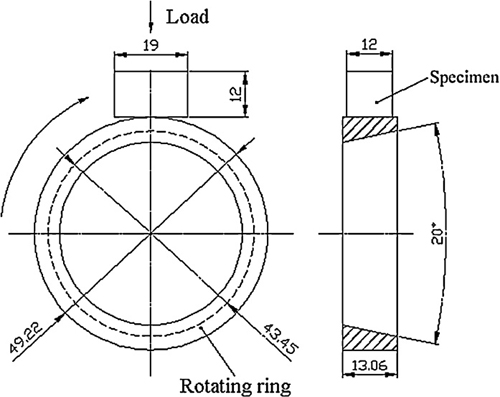

Schematic contact diagram of the frictional couple (unit: mm). (Image by LICP)