Nickel aluminium based intermetallic compounds have several potential applications including high temperature dies and moulds, furnace fixtures, cutting tools, pistons and valves and various components within gas turbines. Because sliding contact at elevated temperatures could occur in many potential applications of NiAl intermetallic materials, it is important to study their tribological behavior under sliding conditions.

According to a study by researchers at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), the incorporation of Cr(Mo) evidently enhanced mechanical properties and improved tribological properties at elevated temperatures of NA.

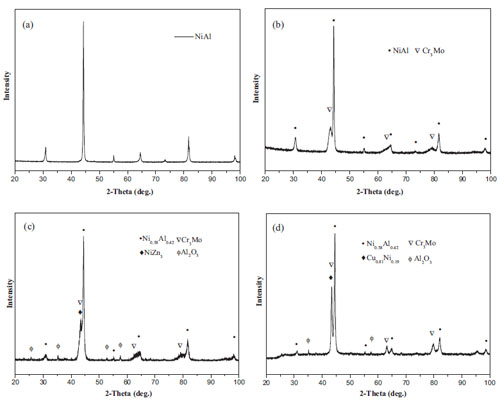

They fabricated NiAl, NiAl–Cr–Mo alloy and NiAl matrix composites with addition of oxides (ZnO/CuO) were by powder metallurgy route and studied their tribological behavior. It was found that some new phases (such as NiZn3, Cu0.81Ni0.19 and Al2O3) are formed during the fabrication process due to a high-temperature solid state reaction.

The results indicated that NiAl had high friction coefficient and wear rate at elevated temperatures, while incorporation of Cr(Mo) not only enhanced mechanical properties evidently but also improved high temperature tribological properties. Among the sintered materials, NiAl matrix composite with addition of ZnO showed the lowest wear rate at 1000℃, while CuO addition into NiAl matrix composite exhibited the self-lubricating performance and the best tribological properties at 800℃.

The work has received support from the National Natural Science Foundation of China and National Program on Key Basic Research Project of China (973 Program). The findings have been published in Wear (Wear 274– 275 (2012) 423– 434).

XRD patterns of the sintered samples: NA (a), NC (b), ZN (c) and CU (d).