Porous materials such as sponges, textiles, and metal meshes are good candidates for oil–water separation, due to their large pore volume, flexibility, and commercial availability. However, these materials suffer from large coincident water absorption along with the oil. To mitigate this problem, various research groups have tried to establish opposite wetting behavior to water and oil on porous materials through designing surface textures and chemistry rationally in different ways. However, some of the techniques are either laborious or substrate restricted, while others show disadvantages of low selectivity and limited recyclability. Thus, developing a versatile and efficient approach to produce materials that can separate oils from industrial wastewaters, polluted oceanic waters, and oil-spill mixtures has become an urgent demand.

The research group for composite lubricating materials at the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has developed the dip coating approach to produce three functionally porous materials used for oil–water separation. Fabric, copper mesh, and sponge are endowed with superhydrophobic property by modification with H-SiO2-PFW through a dip coating process.

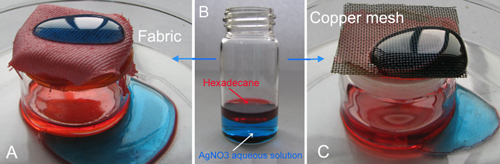

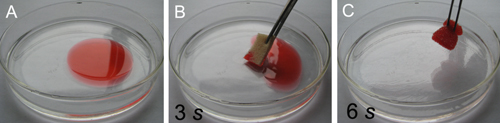

The obtained functional materials can be applied as the separation membrane and oil sorbent scaffold to separate oil from water efficiently, owing to their superhydrophobicity and superoleophilicity. It is found that water droplets can roll off these material surfaces easily, while organic liquids such as hexadecane can wet them completely. These functional materials used for oil–water separation also possessed good reusability, evidenced by 10 cycles of oil–water separation test.

The approach to develop the oil–water separation materials offers benefits of versatility, simplicity, and cost efficiency and is hoped to extent the use of oil–water separation materials in applications.

The findings have been published in Journal of Colloid and Interface Science(432 (2014) 105–108) .

The superhydrophobic fabric (A) and superhydrophobic copper mesh (C) used for oil–water separation. Hexadecane (colored with oil red) easily pass through the fabric and copper mesh, whereas water droplets (AgNO3 aqueous solution, dyed with methylene blue) bead up on their surfaces. (Image by ZHANG Zhzozhu et al.)

Optical images for the removal of the hexadecane film (dyed with oil red) spreading on the water surface using the as-prepared superhydrophobic sponge. (Image by ZHANG Zhzozhu et al. )