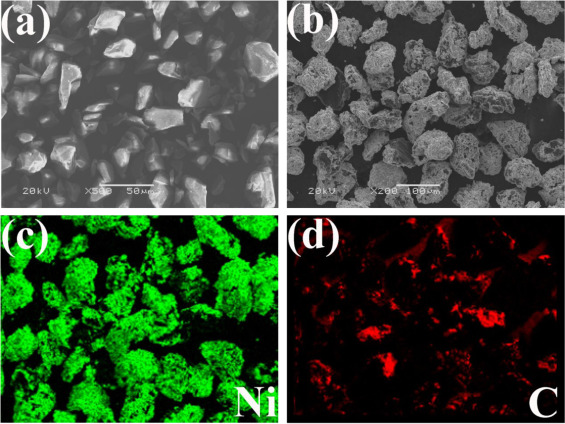

Abstract: With the combination of self-lubricating ability and mechanical property, high-performance ceramic graphite composite coatings are potential candidates for machine components. Mullite/nickel cladded graphite (Ni-graphite) composite coatings with different content of graphite were fabricated by air plasma spraying technique. Results show that doping a suitable amount of Ni-graphite could greatly reduce the defects of mullite coating without significant decrease of their hardness. With the formation of re-graphitization lubricating film on friction surface, the friction coefficient of composite coating with 20 wt% Ni-graphite was observed to be 0.28, which was approximately 52% lower than that of pure mullite coating, and its wear rates was 4.15 times lower than that of pure mullite coating. KeyWords Plus:WEAR BEHAVIOR; HYBRID COMPOSITES; STAINLESS-STEEL; THERMAL SPRAY; FRICTION; RESISTANCE; ATMOSPHERE; CORROSION; CARBON Published in TRIBOLOGY INTERNATIONAL, 101 168-177; 10.1016/j.triboint.2016.04.028 SEP 2016

|