You must have heard of 3D printing. And you may think that the technology can print almost everything, from baby diapers to spacecrafts. In fact, the technology, given the restrictions of its inks, currently mostly made of acrylic esters and epoxy resins, is far from being that versatile. Acrylic esters and epoxy resins do not possess the required characteristics to forge products for the use in tough conditions. Therefore, the products produced via 3D printing are mostly used just for design, display and prototyping.

But here comes some good news. The Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences has achieved a new breakthrough in 3D printing. Researchers there have developed the solvent-free and photocurable polyimide ink for stereolithography apparatus (SLA) and digital light processing (DLP) 3D printing. The ink boasts a glass transition temperature which is greater than 200℃, and the new material possesses excellent solubility, which is a key property for the development of high performance polyimide ink for 3D printing. When processed by a conditioning oven at a temperature of 300℃ or immersed in hot oil, the items printed with the new polyimide ink show no signs of fractures or flexural deformation, which means the rendered material could endure constant heat at high temperatures.

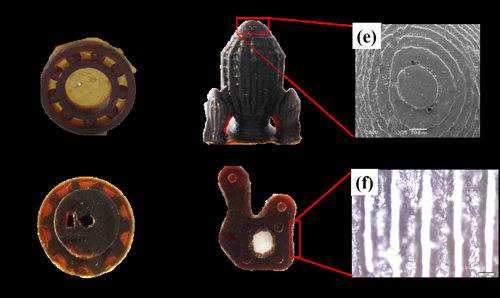

The new ink works wonders in producing spare parts and components with extremely complex shapes, delicate structures, and other special properties, such as good heat resistance, chemical inertness, excellent solubility and high mechanical strength. It means there is huge potential for the technology to be applied in a wider range of industries, such as machinery, electronics, aerospace aviation, and automotive industry. And 3D printing will become faster, more precise and more practical, thanks to the new progress in the ink materials for the technology.

The researchers have published their finding in the Journal of Materials Chemistry. (Solvent Free and Photocurable Polyimide Inks for 3D Printing, J. Mater. Chem. A DOI: 10.1039/C7TA01952A developed by LICP )

This project has received support by the West Light Foundation of China Academy of Sciences, the Special Recruitment Project of LICP, the Natural Science Foundation of Gansu Province (1606RJZA051) and Gansu Puruite Technology Co., Ltd.

Contact :

WANG Xiaolong ZHOU Feng

State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou,

E-mail: wangxl@licp.cas.cn zhouf@licp.cas.cn